The outstanding range of profile systems, hardware options and machinery available today should make it easy to create high quality, technically superior windows and doors which customers will love. But what stands in the way of getting the maximum return from these constituent parts?

"Simply changing the type of screw or the reinforcement can easily solve many of the PVC-U fabrication issues that we see every day. Here is a brief fastener troubleshooting guide for PVC-U"

Ultimately it comes down to attention to detail, and nowhere is this more apparent than with the choice and application of a window or door’s smallest components – the fasteners. Without understanding what the fasteners are capable of or by choosing the wrong screws for the different aspects of the window or door, your ability to deliver on quality promises will be seriously undermined – with costly reputational damage resulting. But that’s not the only harm that poor fastener choice or application could do – it also reduces the efficiency of your production lines and makes fabrication unnecessarily difficult and less safe for your production operatives.

Simply changing the type of screw or the reinforcement can easily solve many of the PVC-U fabrication issues that we see every day. Here is a brief fastener troubleshooting guide for PVC-U.

Screw jamming when fixing into reinforcement with a ‘V’ groove Change the fastener or use a different type of reinforcement.

Occasionally, reinforcement sections incorporate a ‘V’ groove in order to provide rigidity along the length of the steel. Where this coincides with a screw position, the drill point may jam into the groove causing snapping problems. The solution can be to change the type of fastener. Because of the slower speed of insertion, a metric threaded alternative may alleviate the problem, although a flat surface on the steel would ultimately provide a better solution.

Fastener jamming in multi-chamber profiles Change to a metric threaded screw.

When fixing to multi-chamber profiles, the spaced thread of CSR type screws grips the PVC-U and drives the screw into the steel, sometimes at a faster rate than the drill point is able to drill. This may cause jamming problems. The finer thread of a metric threaded screw grips the PVC-U less well and allows the screw to spin within the profile, giving the fabricator more control.

Corrosion is occurring on friction stays after a very short period in-situ Change to a special friction stay screw.

Friction stays are not designed to be fixed to the profile using a countersunk screw. If you do use one to fix through a non-countersunk hole in a friction stay, this will cause mechanical damage to the plating of the screw, leaving the exposed unprotected steel. This will certainly result in corrosion problems. Overcoming this issue is simple – always use a specialist friction stay screw.

Doorset featuring flag hinges is suffering ‘sash drop’ Change to a special 4.8mm diameter screw.

Where flag hinges are being fitted, a standard 3.9mm diameter screw may not fill the countersunk hole or recess fully. This can be one of the causes of ‘sash drop’, which is a common call-back issue. One of the easiest ways to eliminate this issue is to use a specialist screw at 4.8mm diameter for a more secure fix.

Matching the fastener to the capabilities of the plastic profile you’re working with Utilise Rapierstar ‘RFMs.

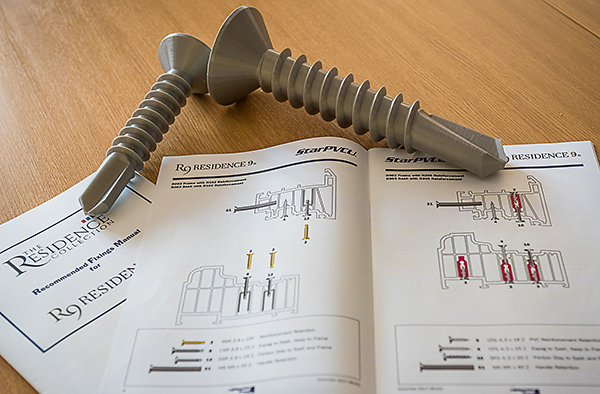

Rapierstar, has developed a range of unique 'Recommended Fixing Manuals' or 'RFMs' for most major profile systems. 'RFMs' indicate correct fastener types in usage and can also enable manufacturers and installers to optimise their screw usage, gaining efficiencies and cost savings.

Big improvements begin with an audit

As these five examples demonstrate, fabrication efficiency and finished quality can be improved instantly with a few small changes. Identifying these issues is key to making improvements, which is where a Rapierstar Fastener Health Check can play a vital role. These in-depth factory audits, conducted by Rapierstar technical specialists, assess whether the right types of fasteners are being used for the many different applications and advise on where changes will deliver benefits.

For further advice on fasteners for PVC-U windows or to arrange a Fastener Health Check contact Rapierstar.

This email address is being protected from spambots. You need JavaScript enabled to view it. Technical & Marketing Manager at Rapierstar Tweet to @andyhol1