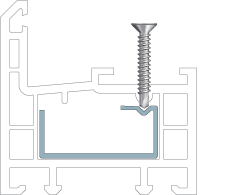

1. Reinforcement

Unsupported ‘U’ section reinforcement flexes under pressure, presenting the drill point with an angled, moving surface which prevents the drill point from performing effectively.

1. Solution

Box section reinforcement provides a stable flat surface which allows the screw to be inserted at 90° to the steel.

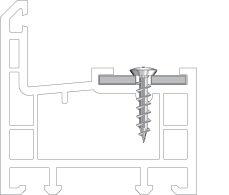

2. Reinforcement

Folded section of reinforcement presents the screw with an impenetrable solid length of steel. The point cannot drill and the screw may either snap or be forced to ‘cock over’ causing hardware problems.

2. Solution

Ensure that the reinforcement presents the screw with a flat and stable surface.

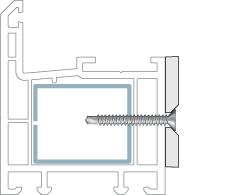

3. Reinforcement

Occasionally, reinforcement sections incorporate a ‘v’ groove in order to provide rigidity along the length of the steel. Where this coincides with a screw position, the drill point may jam into the groove causing snapping problems.

3. Solution

Because of the slower speed of insertion, a metric threaded alternative may aleviate the problem, although a flat surface on the steel would provide a better solution.

4. Multi-chambers

When fixing to multi-chamber profiles, the spaced thread of our CSR type screw grips the PVCU and drives the screw into the steel, sometimes at a faster rate than the drill point is able to drill. This may cause jamming problems.

4. Solution

The finer thread of a metric threaded screw grips the PVCU less well and allows the screw to spin within the profile, giving the fabricator more control.

5. Friction Stay

Using a countersunk screw through the non-countersunk hole in a friction stay will cause mechanical damage to the plating of the screw, leaving exposed unprotected steel. This will certainly result in corrosion problems.

5. Solution

Always use a specialist friction stay screw.

6. Flag Hinge

Where flag hinges are being fitted, a standard 3.9mm diameter screw may not fill the coutersunk hole or recess fully, possibly resulting in ‘sash drop’.

6. Solution

A specialist screw at 4.8mm diameter may be the solution. Always use a screw of the correct diameter.